In the Spaggiari Industria Gomma laboratories, each product is a masterpiece.

With over 70 years of experience, we prefer a constant monitoring of the whole production cycle through a management system quality which has given us the highest recognition from the main certification bodies.

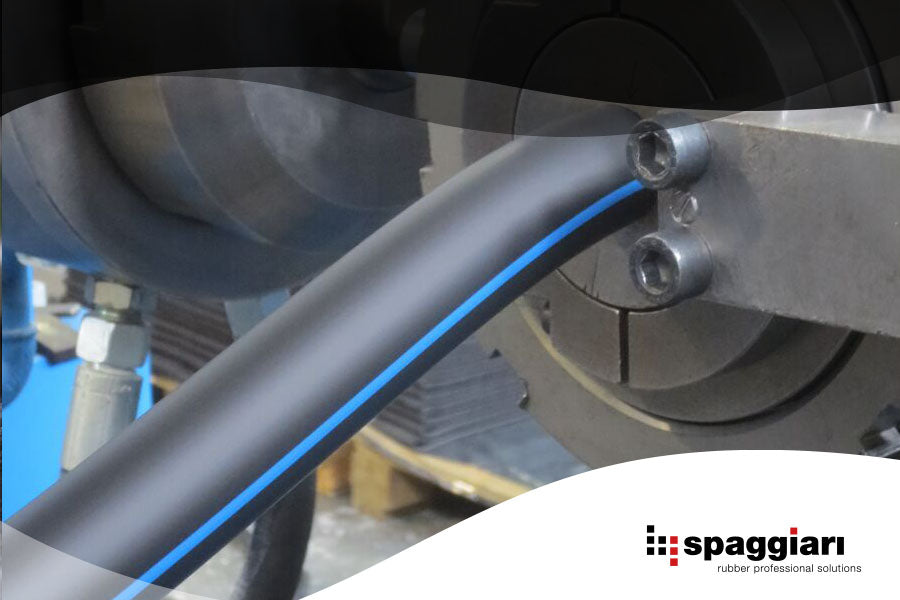

One of the stages involved in the manufacturing of rubber is described below.

What is extrusion?

Extrusion is an industrial production process of deformation that allows to obtain pieces with a constant section, such as tubes, bars, profiles and sheets.

Simply put, it is a method of passing a material in a pasty state through a matrix with the desired shape, thus obtaining an object with the same cross-section.

Direct or reverse?

Extrusion can occur according to two methodologies:

- Direct extrusion

In the Shell of direct extrusion, the material is compressed on one side by the piston and comes out on the opposite side, where the die is positioned. In other words, the direction of the material flow is in accordance with the motion of the piston. In this case, the force required for extrusion decreases constantly as the quantity of material to be extruded inside the container decreases. In the final part of the process, there will be an increase in the force required for extrusion because the material, having become very thin, will be able to come out radially from the die.

- Reverse extrusion

In the Shell of reverse extrusion, however, the matrix is integral with the piston, which has a central cavity to allow the extruded product to exit in the opposite direction to the motion of the piston.

In reverse extrusion there is the advantage of having lower friction forces. In fact there is no relative motion between the material and the container wall. The pressures that can be exerted by the action of the piston are lower than in the Shell of direct extrusion and remain almost constant during the entire duration of the process.

Coextrusion

A variant of the extrusion process is coextrusion, in which different materials are processed simultaneously, which exit the die coupled, so that, for example, gaskets are obtained with a rigid core (which acts as a support) and a soft external part (which guarantees good hermetic sealing).

Conclusions

If you are looking for a customized or custom-made rubber product, contact us by email at info@spaggiarigomma.it or call the number 0522 825808 to receive more information. One of our operators will respond as soon as possible with a personalized proposal.